So I am guessing it is one of two cases: either you are reading this because you are a solar PV energy enthusiast and so you have come to the right place, or you are a hot person who is possibly reconsidering their daily consumption of weed, to which I simply react with WHAT IS WRONG WITH YOU THIS IS LITERALLY A RENEWABLE ENERGY BLOG! (and no Greg I am not talking about you, you do get high like crazy but you’re not hot you ugly….sorry mate!)

Having come to terms with the thought of all my Greg-followers/readers blocking my site from their feed (please don’t unfollow me it really was constructive criticism do not unfollow me nooooooo!), I turn my attention to the pressing topic of this post, which is the effect of some undervalued parameters when doing solar PV system sizing, and mainly site elevation and ambient temperature.

A few weeks ago, I was working on designing and sizing various equipment involved in a PV project, and I made a mistake. I did not give due importance to the site elevation and temperature information. I did not ignore those parameters, but in hindsight I considered them more lightly than I should have. Luckily in that case, the ensuing impact was not very big and it ended up being an appropriate lesson I learned for future works (see Greg I am constructive by nature I choose to make the best out of every situation….what is that? You are still gona unfollow after you finish reading? NOOOOOO).

Always size your DC equipment based on your lowest ambient temperature, your AC equipment based on your highest ambient temperature, and always remember to check how your site altitude affects your equipment rating.

Here is the juice of what I learned: when sizing your solar PV system, size your DC equipment based on the lowest ambient temperature, AC equipment based on the highest ambient temperature, and always check how your site elevation might affect the rating of your equipment.

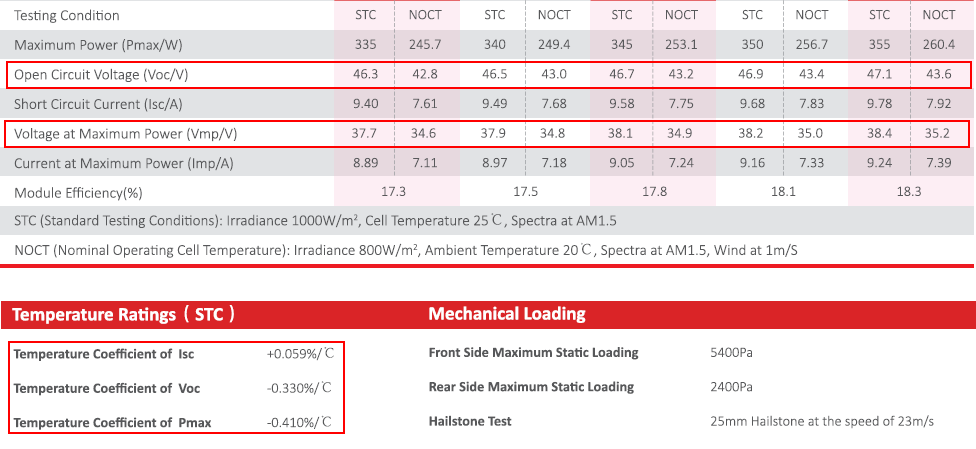

Very low temperatures can significantly increase the DC voltage at which your solar equipment function (e.g. modules, inverters, batteries, etc.), and can very well end up damaging them. All the equipment datasheets should have the relevant information you need to de-rate their operating voltage based on temperature.

For example, a solar module’s operating voltage is spec-ed out at Standard Testing Conditions “STC”, with T=25dC or 77dF. If enough modules were connected in series to almost meet the inverter’s DC operating voltage (let’s say 600Volts DC), chances are the ineverter will burn out, because during many hours of the day the modules will operate at lower temperatures than 25dC, and will consequently INCREASE their operating voltage, surpassing the DC rating of the inverter.

Very low temperature can significantly increase the DC voltage at which your solar equipment function, and can very well end up damaging them.

On the other hand, high ambient temperatures lower the AC rating of the AC equipment (inverters, transformers, cables, etc.). Note that the inverters overlap as both DC and AC equipment because of the nature of their input/output connections. So for example, if your inverter is nominally rated at 5kVA output at 30dC, it will produce less at higher temperatures. Again, the datasheets provided by the supplier should contain the de-rating factors between equipment output and temperature. The same applies for transformers, cables, over-current protective devices, etc. And while this might not damage your inverter or transformer, it can cause serious damage in the case of some AC equipment (e.g. cables would melt and cause a short if undersized).

High ambient temperatures lower the AC rating of the AC equipment.

The elevation’s effect on solar equipment is very similar to that of high temperatures on AC equipment. The higher the site is located, the lower the equipment rating becomes. This info is also readily available with the supplier.

So I say it again folks: Always size your DC equipment based on your lowest ambient temperature, your AC equipment based on your highest ambient temperature, and always remember to check how your site altitude affects your equipment rating.

There you go. Not feeling so Mugglish after all eh? You are welcome. What is that? You think there are more undervalued parameters I forgot to mention? Tell me about that in the comments section, I would be happy to have a conversation about it. Say that again? You want to meet to discuss your sudden urges to invest in a PV system for your home? Your company? BAAM you have come to the right place. Hit me up on my contact info and we can discuss that over a cup of coffee. I am buying!

Leave a comment